Refurbished CNC machines

Refurbished CNC machines

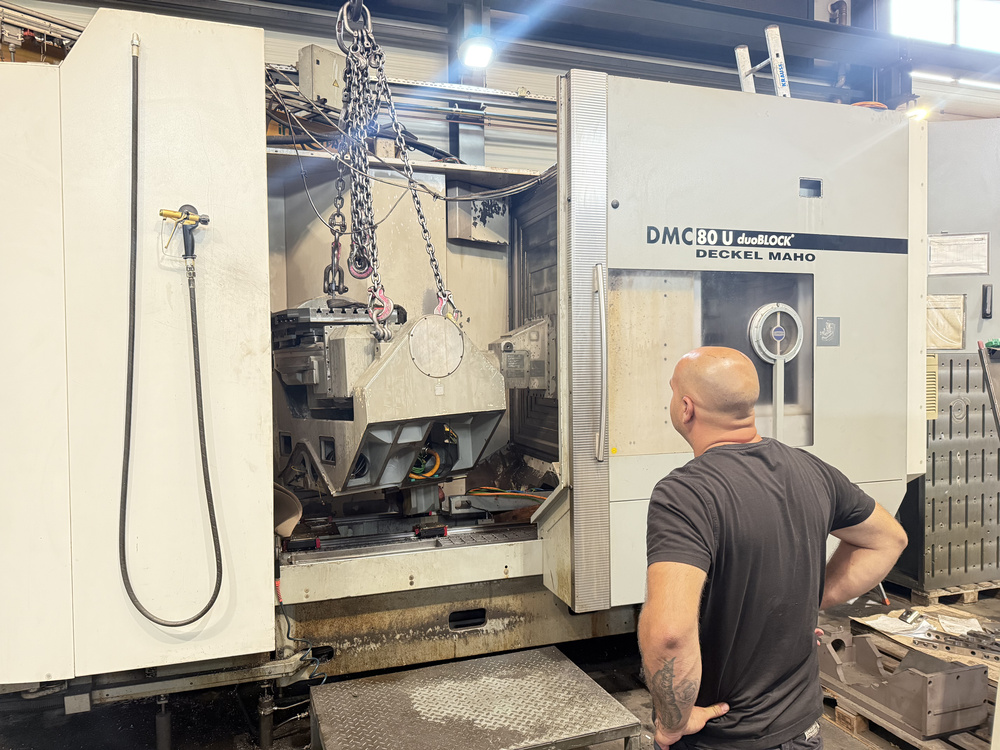

At CNC Elite, we offer professionally refurbished CNC machining machines that are ready for direct integration into the production process.

We keep selected already refurbished machines in stock, and based on customer inquiries we also source a suitable machine, fully refurbish it, and technically adapt it to the customer’s requirements.

The customer therefore does not purchase a used machine, but a technically verified, refurbished, and fully functional CNC system, ready for immediate use.

What a CNC Elite refurbished machine means

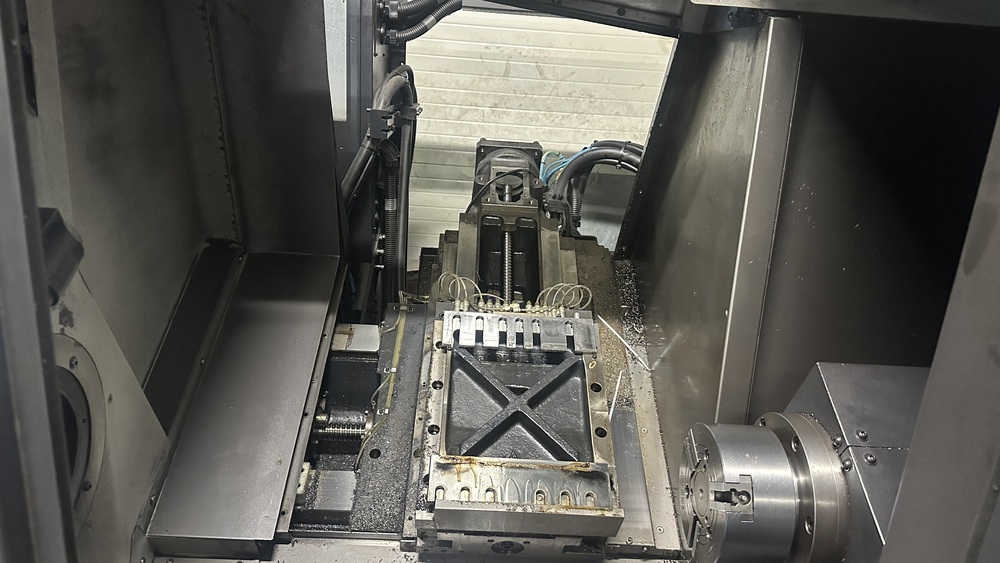

Every refurbished machine at CNC Elite is treated as a complete technical system.

We do not refurbish individual components in isolation; instead, we ensure that all mechanical, hydraulic, pneumatic, lubrication, and control assemblies are mutually coordinated, adjusted, and functionally stable as a whole.

The goal of refurbishment is to ensure that the machine is technically reliable, geometrically accurate, and ready for industrial production.

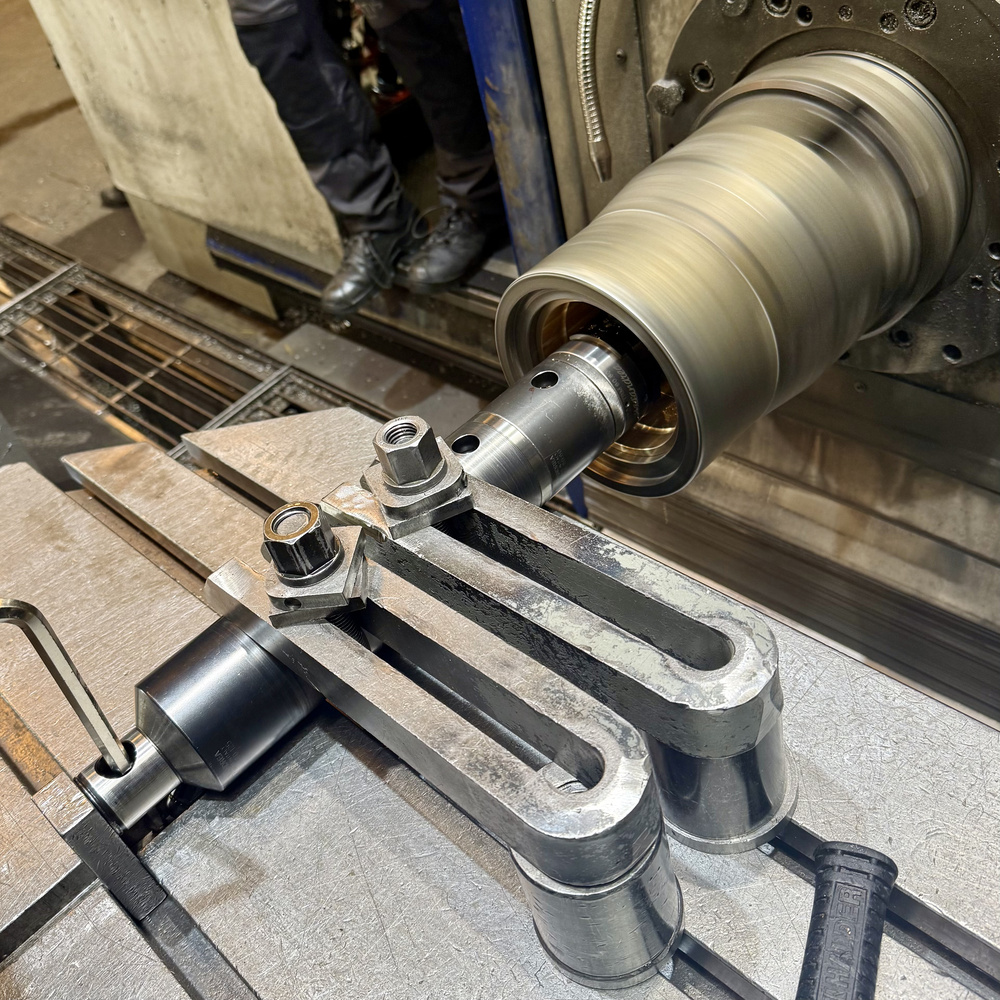

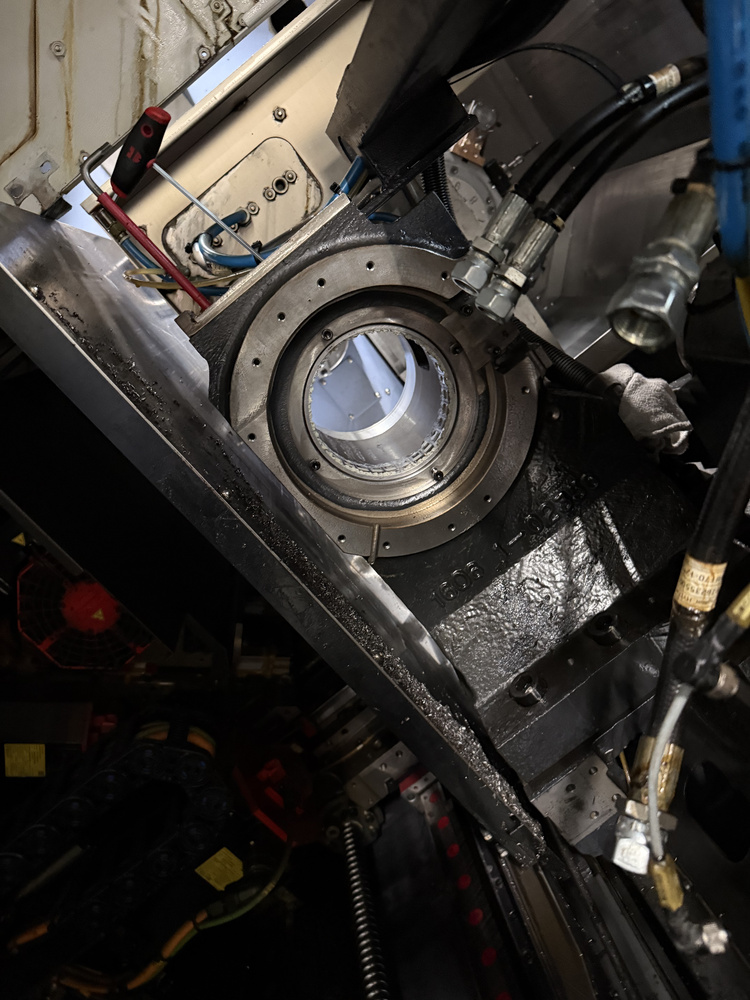

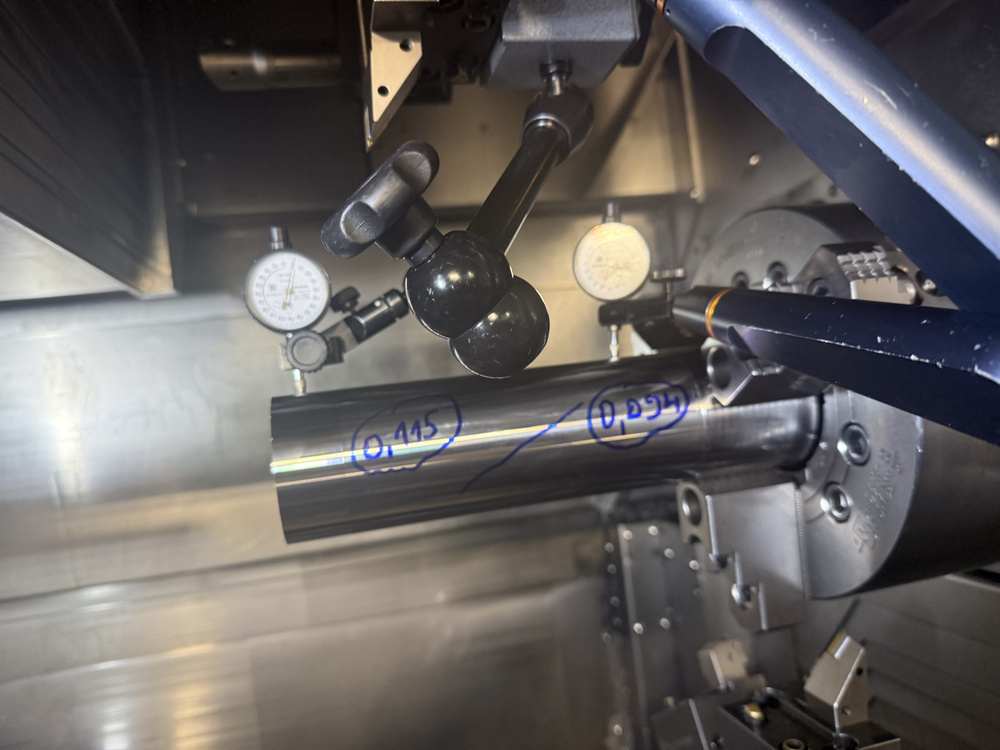

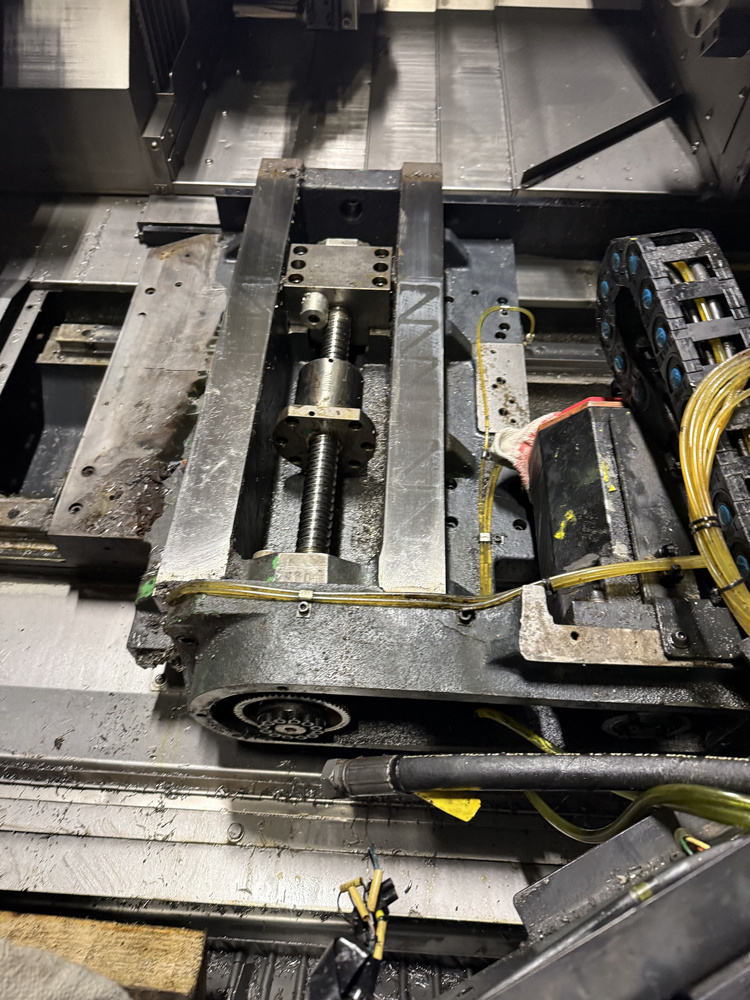

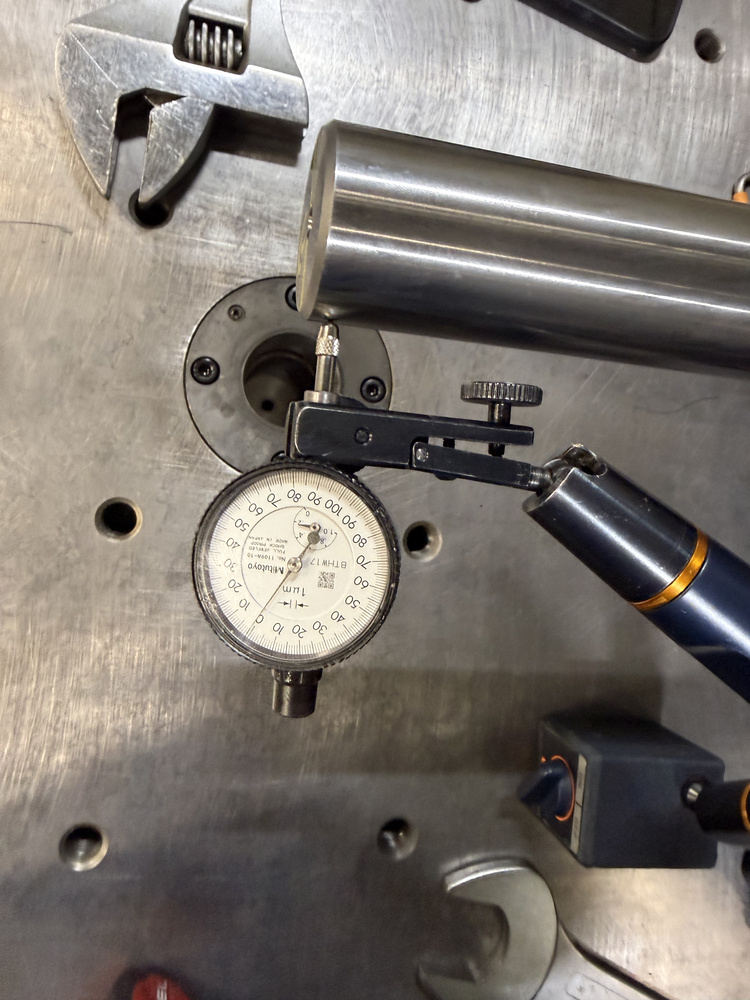

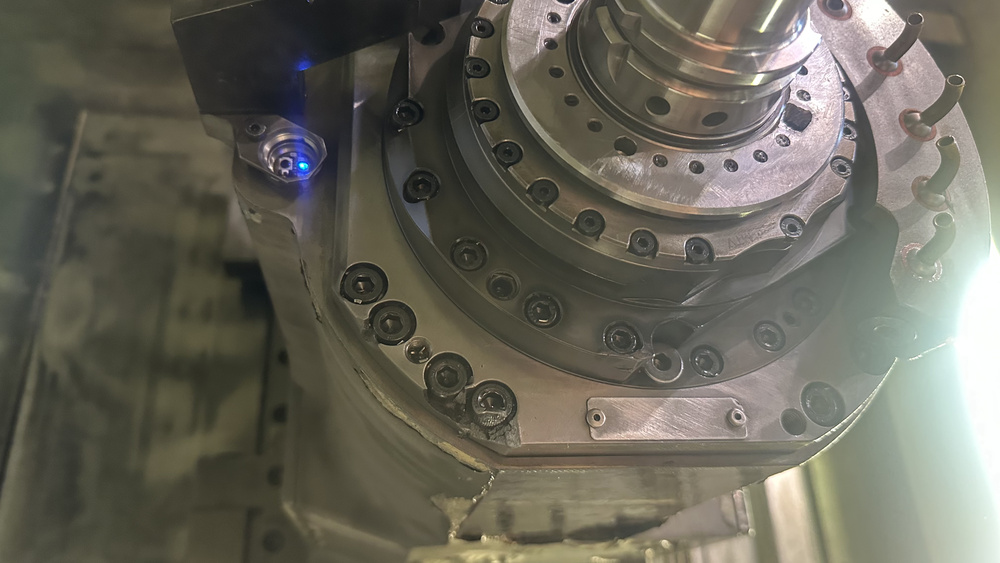

Mechanical system

-

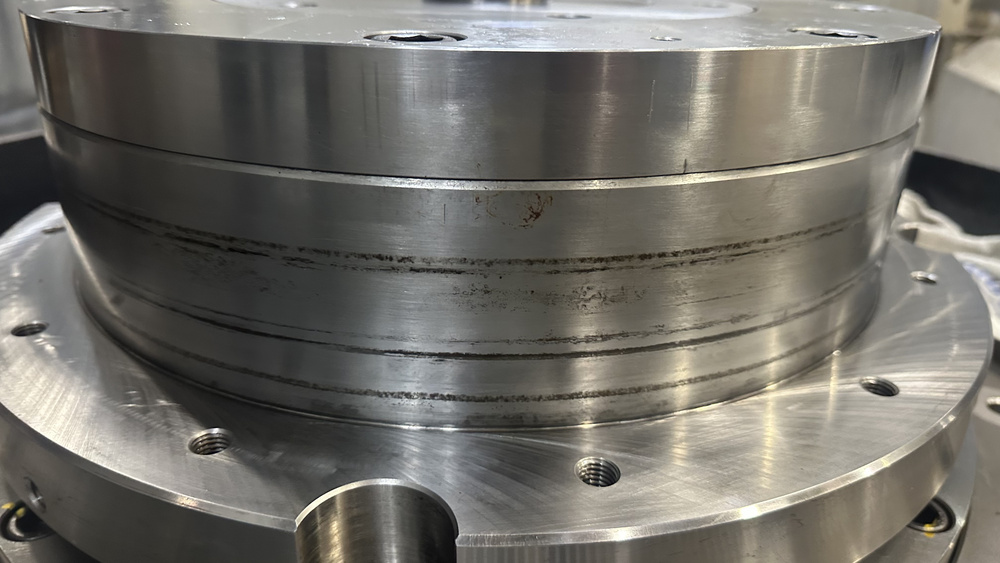

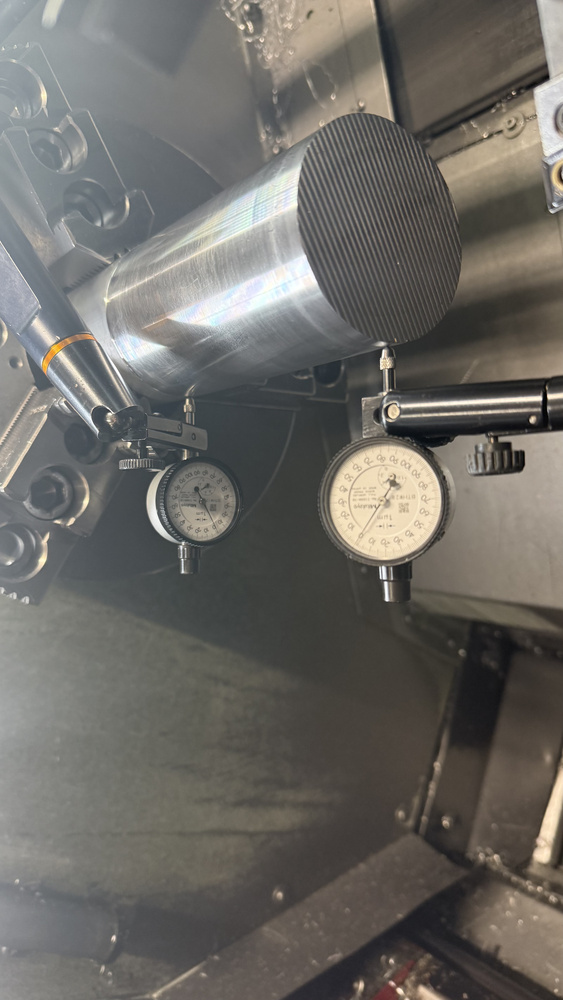

inspection and refurbishment of the main spindle

-

inspection and, if necessary, refurbishment of ball screws and axis drives

-

inspection of guides, bearings, mechanical transmissions, and backlash

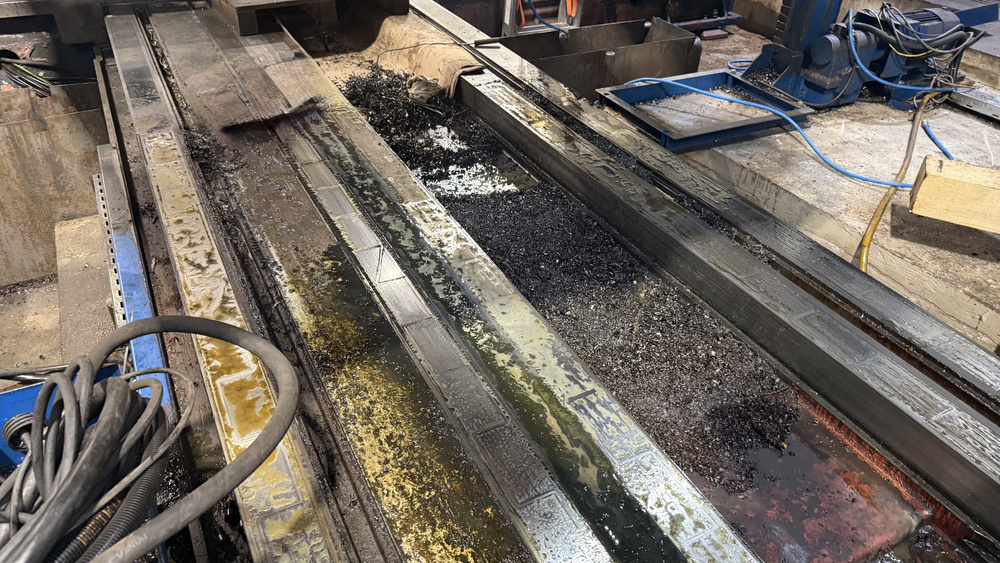

Lubrication system

-

inspection of lubrication system operation

-

repair or replacement of components as required

-

ensured correct and stable lubrication flow to all critical machine points

Pneumatic system

-

inspection of valves, regulators, and connections

-

elimination of leaks, pressure drops, and unstable operation

Hydraulic system

-

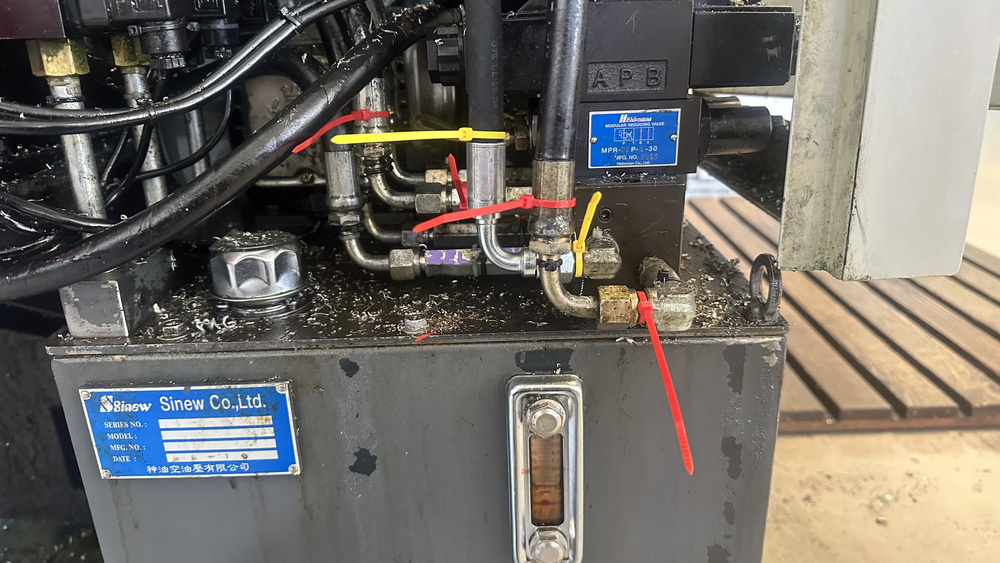

inspection of pressures, stability, and operation

-

repair or adjustment of components to ensure reliable operation

Electrical and control system

-

functional inspection of servomotors and axis drives

-

verification of encoders and feedback systems

-

testing of the main spindle drive

-

inspection of the CNC control, I/O modules, and communication

-

verification of operational stability in real machine operation

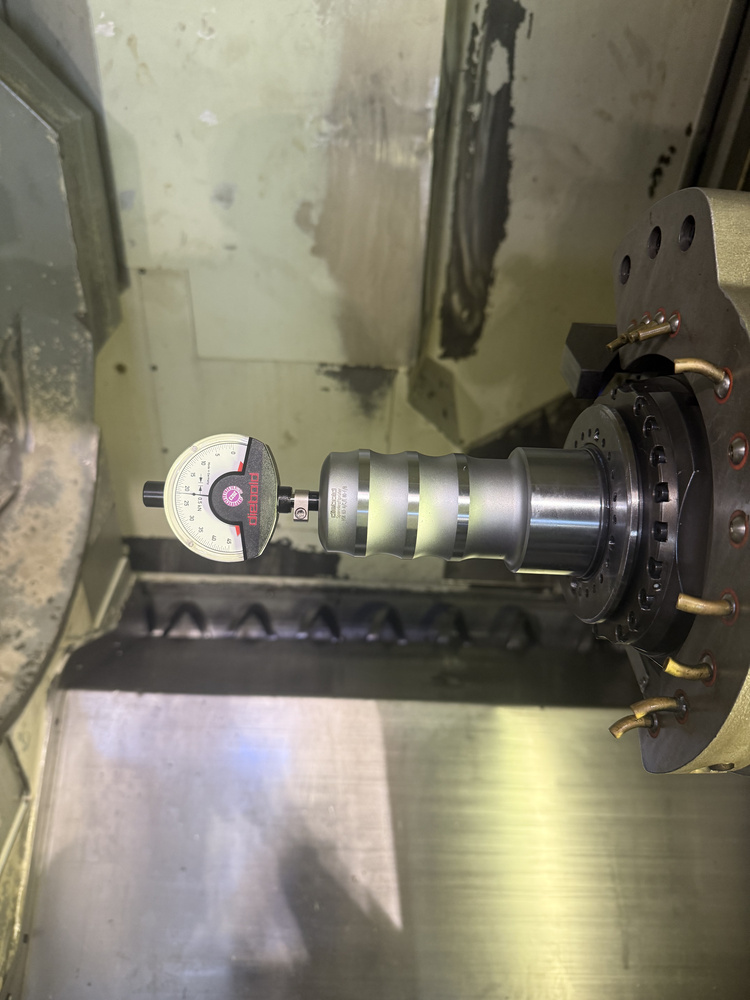

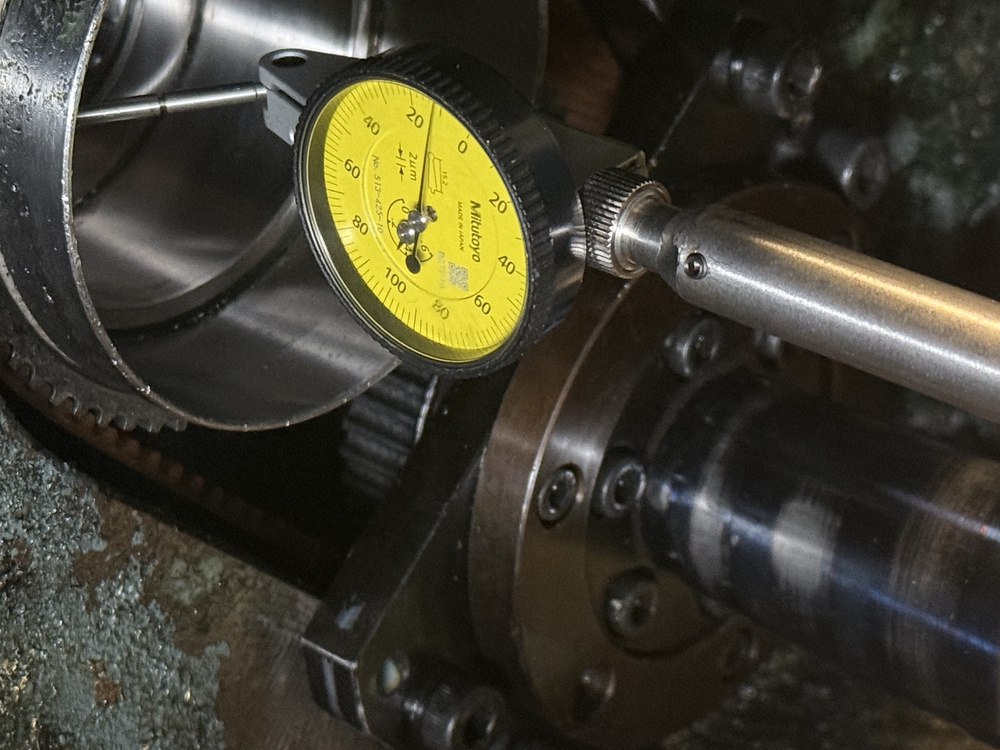

Geometry and accuracy

-

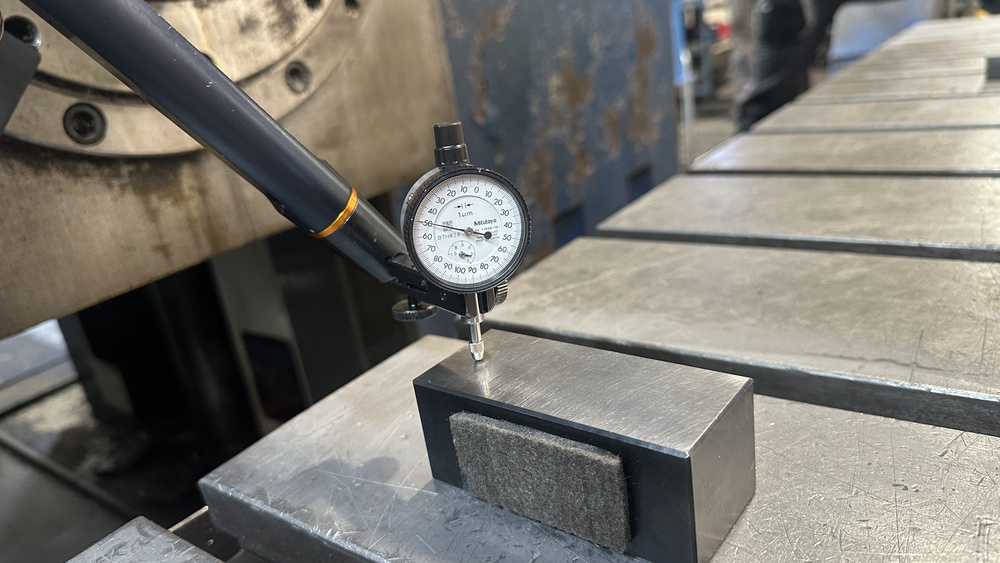

adjustment of machine geometry according to a measurement protocol

-

axis alignment, compensations, and mechanical correction

-

ensured geometric accuracy of the machine

The machine is ready for industrial use

Each machine leaves CNC Elite only when:

-

all systems are inspected and coordinated

-

mechanical and control parameters are set

-

geometric adjustment has been completed

-

the machine is capable of stable, repeatable, and accurate operation

The customer receives an operational production machine, not a project requiring further repairs.

Installation and technical commissioning at the customer

To ensure correct operation in a real production environment, we provide:

-

installation of the CNC machine

-

leveling and mechanical alignment

-

initial technical commissioning and operational verification

-

optimization of basic parameters for stable operation

Training and CAM integration

If required, we provide:

-

training of operators and technologists on the specific machine

-

assistance with postprocessor setup (CAM → CNC)

-

verification of NC program output correctness

This ensures that the machine is fully integrated into your existing production process.

12-month warranty

We provide a 12-month warranty for refurbished machines, which includes:

-

pneumatic system

-

lubrication system

-

hydraulic system

-

mechanical assemblies (main spindle, axis ball screws, key mechanical components)

-

guarantee of geometric accuracy

How the purchase process works

-

You send an inquiry with your requirements

-

We propose a suitable machine (from stock or for refurbishment)

-

We perform professional refurbishment and technical verification

-

We deliver the machine, install it, adjust it, and hand it over for use

Refurbished machines – coming soon

Several refurbished CNC machines are currently undergoing refurbishment and technical verification.

Publication of individual models with specifications and prices will follow shortly.

For timely information and reservations, please contact us.

Sodelujemo z raznimi podjetji, tako doma kot tudi v tujini:

Mojstrovina d.o.o., Kovinostrugarstvo Korez d.o.o., Tajfun Planina d.o.o., Formateh d.o.o., Tehnos d.o.o., Mariborska Livarna Maribor d.d., Sij Metal Ravne d.d., NCM d.o.o., Impol d.o.o., Radkersburger Metal Forming GmbH, Robotehnika d.o.o., Izoelektro d.o.o., Palfinger d.o.o., Livar d.d., Impro storitve d.o.o., Monter Dravograd d.o.o., Lar transportni sistemi d.o.o., Iskra PRO Kranj, d.o.o., Knez d.o.o., Miheu d.o.o., Fewi d.o.o., Inkos d.o.o., Fortis d.o.o., Žust-Al d.o.o., Jokmi d.o.o., Schvab d.o.o., Fibmarkt d.o.o., Koviflex d.o.o., Los automation d.o.o., Vitli Krpan d.o.o., Talum d.d., Mebor d.o.o., Tehnika set d.o.o., Impol d.o.o., Akošir d.o.o., Ramax d.o.o., Marovt d.o.o., SMM d.o.o., Sublimo tehnologije d.o.o., ter z več kot 70-imi samostojnimi podjetniki.